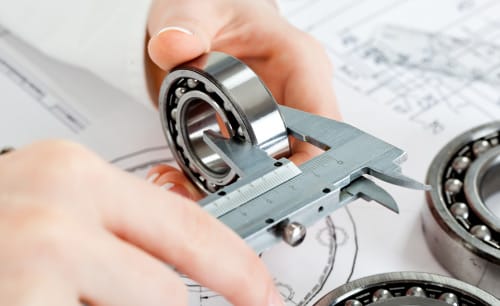

Kastel Karlovo JSC is a leading company with subject of activity: trade with rolling bearings, abrasives and diamond tools, belts, steel wire ropes, chains, slings and lifting accessories; manufacture of various types of slings.

In Bulgaria our clients are over 700 private and state enterprises from the energy, mining, chemical, metallurgy, mechanical engineering, port, electro- and rail- transport, construction and many others industries.

To this day, we continue to write the pages of a story – our story – together with you. Be a part of it!

История

The first registration of the company as Kastel Export Ltd.

Import & Export Department has been established.

The company becomes the Exclusive Representative for Europe of the American company KBS LLC for the supply of rolling and sliding bearings..

Successfully is introduced quality system ISO 9001:2000

The company becomes an Authorised Distributor for the territory of Bulgaria of NSK, Japan /bearings/

The company becomes an Authorised Distributor for the territory of Bulgaria of Saint-Gobain Abrasives, France /abrasives/

The company becomes an Authorised Distributor for IKO, Japan /bearings/

Kastel Export Ltd. expands its product range with the supply of steel wire ropes and accessories.

The construction of the central building and warehouse of the company in the town of Karlovo has been completed.

Kastel Karlovo JSC is founded as a successor of Kastel Export Ltd.

The company becomes an Authorized Distributor for Bulgaria of GATES BVBA PT / industrial belts /.

During this year the number of current nomenclatures exceeded 10,000; and the average – monthly stock – 4,500,000USD.

2016

The company becomes an authorized distributor of Koyo / JTEKT bearings, Japan.

A new warehouse of nearly 500 square meters has been built.

Kastel Karlovo JSC starts the manufacture of slings!

The company acquires a fully computerized hydraulic stand that is used to test the finished products /slings/.

The company invests in a state-of-the-art German 1500 ton four-column hydraulic press machine for the production of slings as well as 6 industrial sewing machines made by Duerkopp-Adler Germany.

A new warehouse is under construction.

27.06.2020г on this date the company celebrates its 25th anniversary

2020

The company becomes an authorized distributor for Bulgaria of MIPROMET lifting equipment.

2022

Kastel Karlovo AD becomes a certified aip-Partner of NSK – increasing productivity, reducing costs and finding solutions.

2023

The company becomes an authorized distributor for Bulgaria of TIMKEN bearings, USA.

Kastel Karlovo JSC becomes a member of EPTDA – a leading industry association in Europe, the Middle East and Africa.